| East Industrial Zone, Anping, Hebei, China. – Pekín – China, Bahía Bohai | +86-318-18220891 | |

| http://www.tower-packing.org | ||

| Industria > OTHERS | ||

| Pekín (China, Bahía Bohai) - Cochabamba (Bolivia) | Pekín (China, Bahía Bohai) - Aracaju (Brasil) |

| Pekín (China, Bahía Bohai) - Buenos Aires (Argentina) |

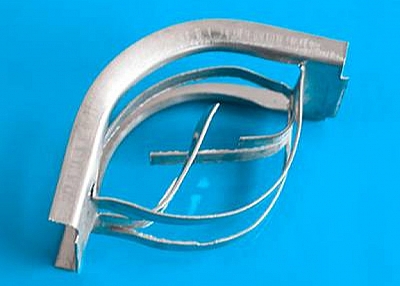

Metal Intalox Saddle - an Acr-Shape Random Packing

Metal intalox saddle, also called metal intalox saddle ring, is one of the most widely used random packings. Metal intalox saddle ring, composed by annulus and saddle, has two curves (top camber is elliptic curves while bottom one is semicircular curve). It is generally made of stainless steel or carbon steel, which makes it possess higher packing strength and better stiffness than plastic intalox saddle. The four most popular sizes of metal intalox saddle ring, widely applied to industrial manufacture, are 25#, 38#, 50# and 70#.

This is a piece of metal intalox saddle ring.

MIS-01: Metal intalox saddle ring is composed by annulus and saddle.There is a structure diagram of metal intalox saddle from front view.

MIS-02: Metal intalox saddle has high strength and low cost.

This is a structure diagram of metal intalox saddle ring from top view.

MIS-03: Metal intalox saddle ring is widely applied to industrial manufacture.

Specification - stainless steel intalox saddle ring

Model Type Diameter × Height × Thickness

D × H × ? (mm) Bulk number (m-3) Bulk density (kg/m3) Specific surface area (m2/m3) Void volume (m3/m3) Dry packing factor (m-1)

MISS-01 25# 25 × 15 × 0.3 87720 188 171 0. 976 184

MISS-02 38# 38 × 16.5 × 0.4 38160 181 123 0.977 132

MISS-03 50# 50 × 29 × 0.5 11310 141 79 0. 982 83

MISS-04 70# 70 × 35.5 × 0.6 4250 118 55 0. 985 58

Materials: SS 304, SS 316, SS 316L.

Suitable temperature range: less than or equal to 400 °C .

Specification - carbon intalox saddle ring

Model Type Diameter × Height × Thickness

D × H × ? (mm) Bulk number (m-3) Bulk density (kg/m3) Specific surface area (m2/m3) Void volume (m3/m3) Dry packing factor (m-1)

MISS-05 25# 25 × 15 × 0.5 87720 314 179 0. 960 202

MISS-06 38# 38 × 16.5 × 0.6 38160 267 127 0.966 141

MPRS-07 50# 50 × 29 × 0.8 11310 228 82 0. 971 90

MPRS-08 70# 70 × 35.5 × 1.0 4250 197 57 0. 975 61

Suitable temperature range: less than or equal to 350 °C .

Features

Metal intalox saddle has larger void volume. Liquid channels in bed layer mostly are circular arc structures, which reduce the resistance of gas passing. Metal intalox saddle is also high-strength and low-cost.

Application

Metal intalox saddle can be used to drying tower, absorption tower, cooling tower, scrubbing tower and regeneration tower in chemical, metallurgic, gas, environmental protection and many other industries.

Package

Metal intalox saddles are packed in dry boxes which have enough strength to withstand impact.

Tower Packing with High Flux & Small Resistance

Actividad: